Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

How To Reinforce Spalling And Carbonization Of Hydraulic Structures?

Is the gate pier peeling off due to frost?

Is the steel bar in the wharf pile foundation corroded?

Is the carbonization depth of the aqueduct exceeding the standard?

These are common durability challenges facing hydraulic structures:

Hydraulic structures are exposed to constant humidity, allowing moisture to easily penetrate the concrete. When temperatures drop below zero, the expansion pressure from frozen water can corrode the concrete. Chloride ions can also easily infiltrate with the moisture, corroding the internal steel reinforcement. Carbon dioxide can penetrate the concrete atmosphere, reducing its alkalinity and damaging the passivation film on the steel. Freeze-thaw damage and concrete carbonization can severely impact the service life of hydraulic structures.

FRP Pile Jacketing technology, fast repair and long-term protection

For areas with severe freeze-thaw damage and severe concrete carbonization, FRP Jakceting + underwater epoxy grouting repair technology can be used. This technology can be directly constructed underwater to quickly repair damaged concrete areas; it can effectively reduce the impact of factors such as dry-wet alternation, water erosion, and chloride ion erosion, thereby extending the service life of the building.

1. Strong Bonding, Corrosion Resistance, and Long-Term Protection

FRP Jacketing utilizes high-strength fiber composite materials, offering lightweight, high strength, chemical resistance, and UV resistance. Underwater epoxy grouting ensures consistent adhesion to the glass FRP Jacket even in underwater environments, effectively resisting external corrosion and providing long-term protection. It also reduces the effects of factors such as rust and chloride ion corrosion, extending the lifespan of the building.

2. Direct underwater construction, no disruption to navigation.

FRP Jacketing utilizes patented technology for automatic drainage, eliminating the need for cofferdams and large lifting equipment. It can be constructed underwater, occupying virtually no space in navigable waters and preventing disruption to ship traffic.

3. Environmentally friendly and non-toxic, no water pollution.

FRP Jacketing utilizes chemically inert fiber composite materials and epoxy grouting with a natural cardanol curing system. It releases no toxic substances during or after construction, and does not pollute water sources.

4. Customizable Thickness, Shape, and Color

We offer customized production of various thicknesses and shapes to meet varying degrees of damage and various surface repair needs.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

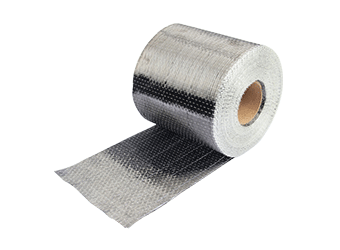

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer(CFRP) plate for structural strengthening and concrete repair

HM-CFN is net alike strengthening fabric which made of carbon fiber tow. As the substitutes of steel mesh, it can be used together with epoxy motar to seal and control the crack, and improve the load capacity of the original structurers